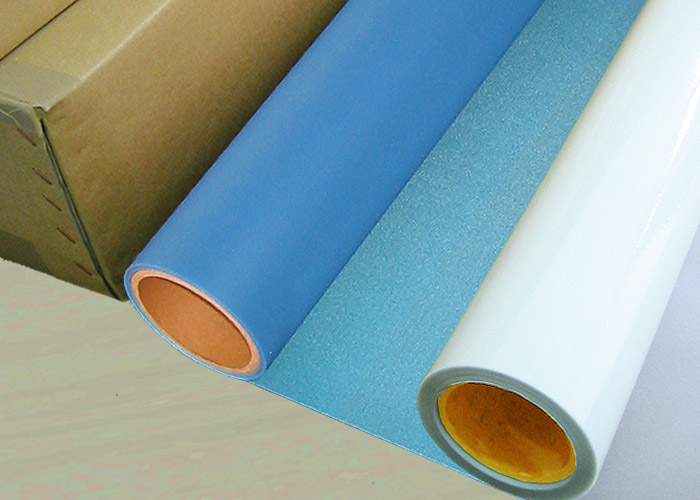

Anti-Marking Film for Sheet-fed Press / Made in Japan

Product Features

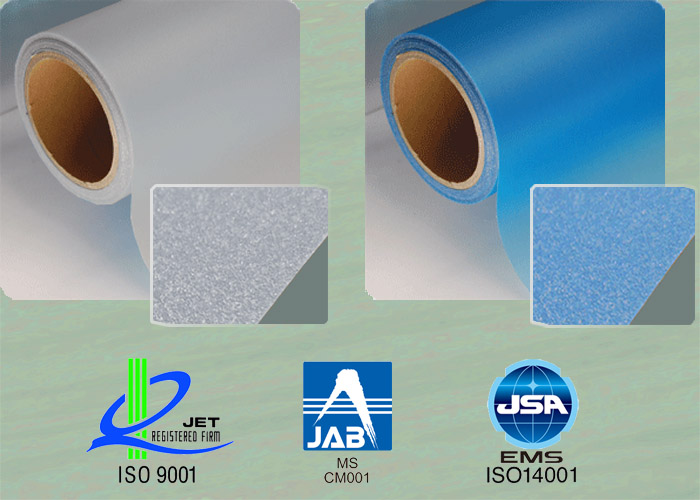

- ISO 9001 certified continuous controlled high quality products

- ISO 14001 Certified Continuous Environmental Consideration

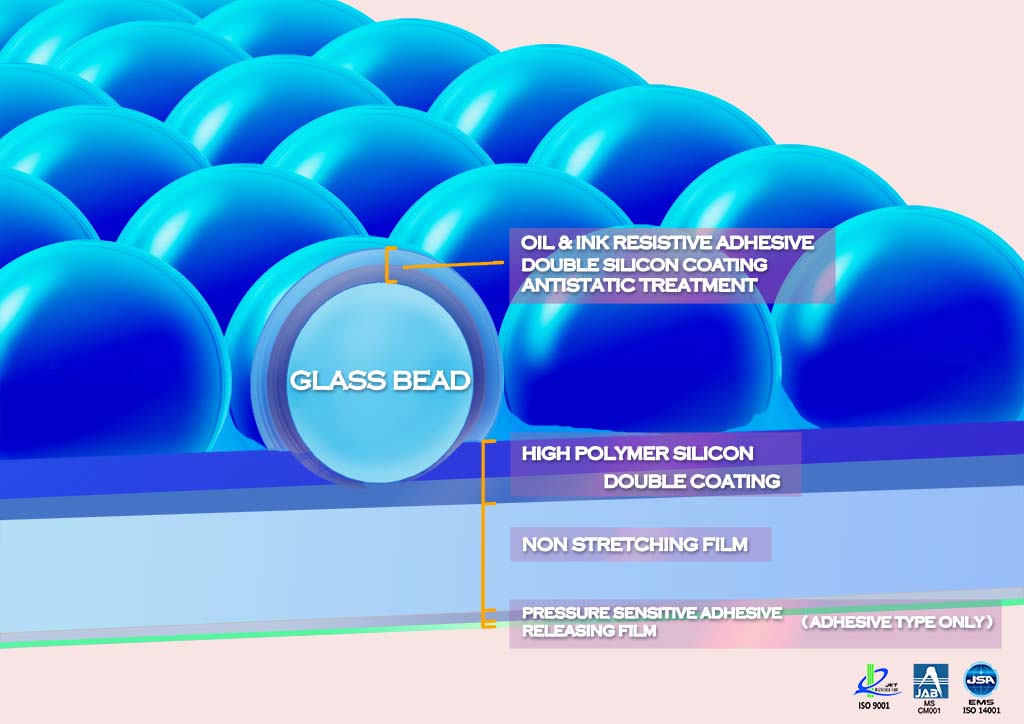

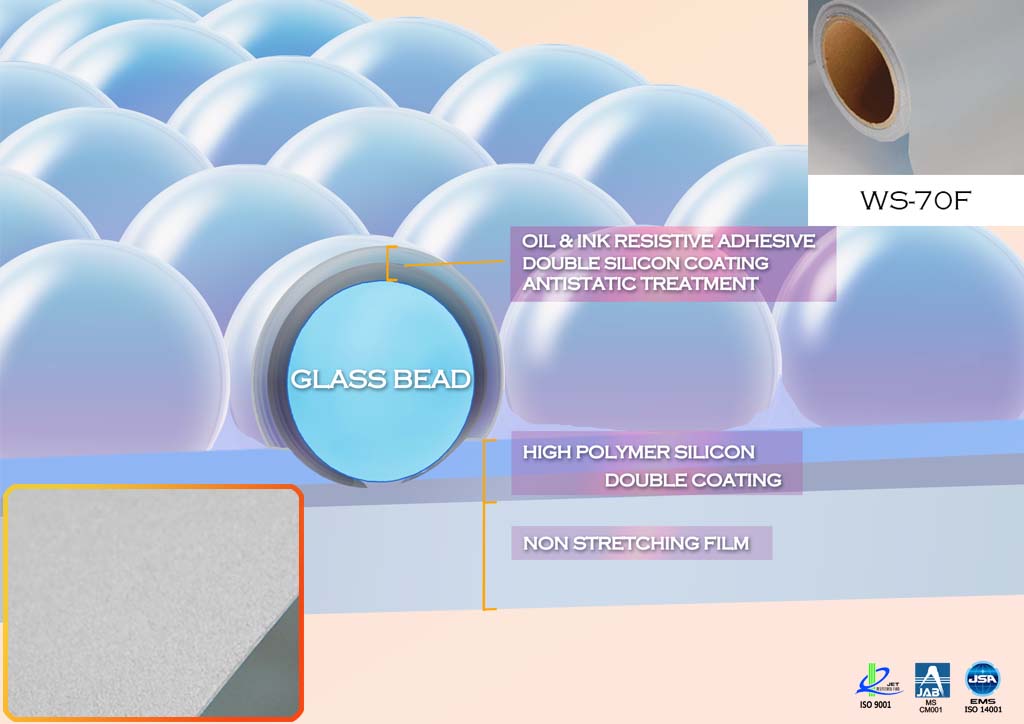

- Regularly embedded glass beads with uniform particles

- High thickness accuracy, no stretching or wrinkling

- Excellent oil resistance, Antistatic and Washability

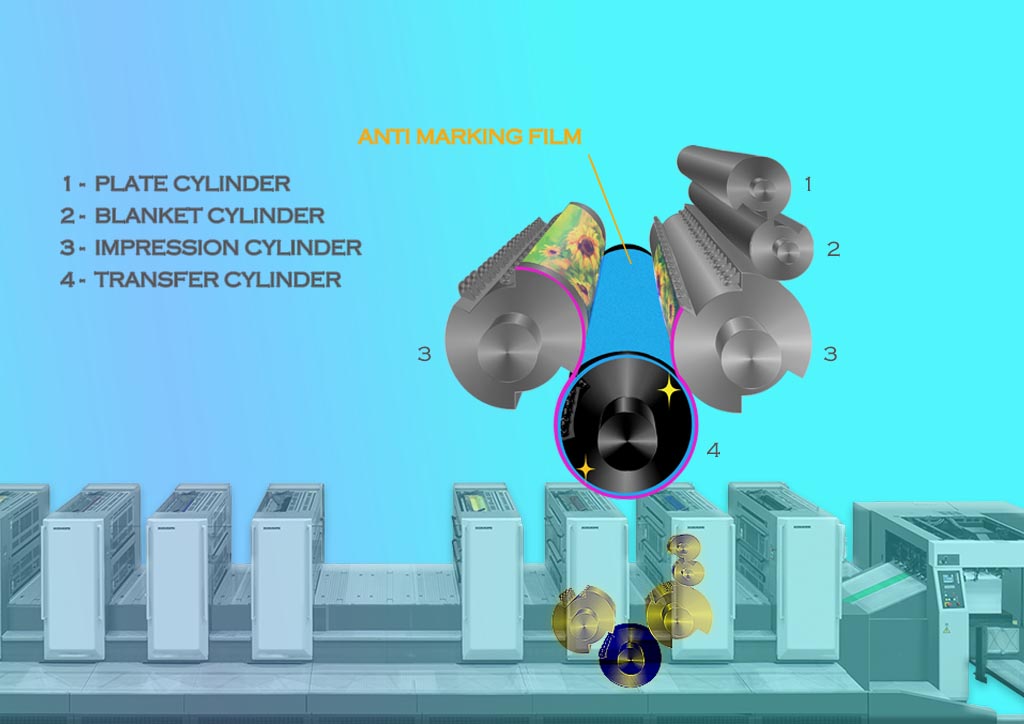

What Is Anti-Marking Film For Sheet-Fed Press?

Anti-marking film is a specialized material used in sheet-fed printing machines to prevent marking or smudging on printed sheets. It is affixed to the transfer cylinder.

Sheet-fed printing machines print on individual sheets of paper or other substrates, one at a time, rather than on a continuous roll of paper. During the printing process, sheets of paper can pick up ink or other substances from the printing press, causing marks or smudges on the printed image.

Anti-marking film is a thin, durable material that is applied to the surface of the printing press to help prevent this from happening.

Why Do We Recommend Our Original Anti-Marking Film?

We supply our original anti-marking film made in Japan with sufficient performance and at a suitable price.

Our production factory is ISO 9001 and ISO 14001 certified for quality and environmental management to ensure the satisfaction and peace of mind of all our customers.

In addition to ISO certification, testing on various major manufacturers’ presses is also important to ensure customer satisfaction and peace of mind.

Our original anti-marking film are supplied with no label, and we also supply under OEM basis to many countries.

Many of our partners are supplying our anti-marking film to the market as their own brand.

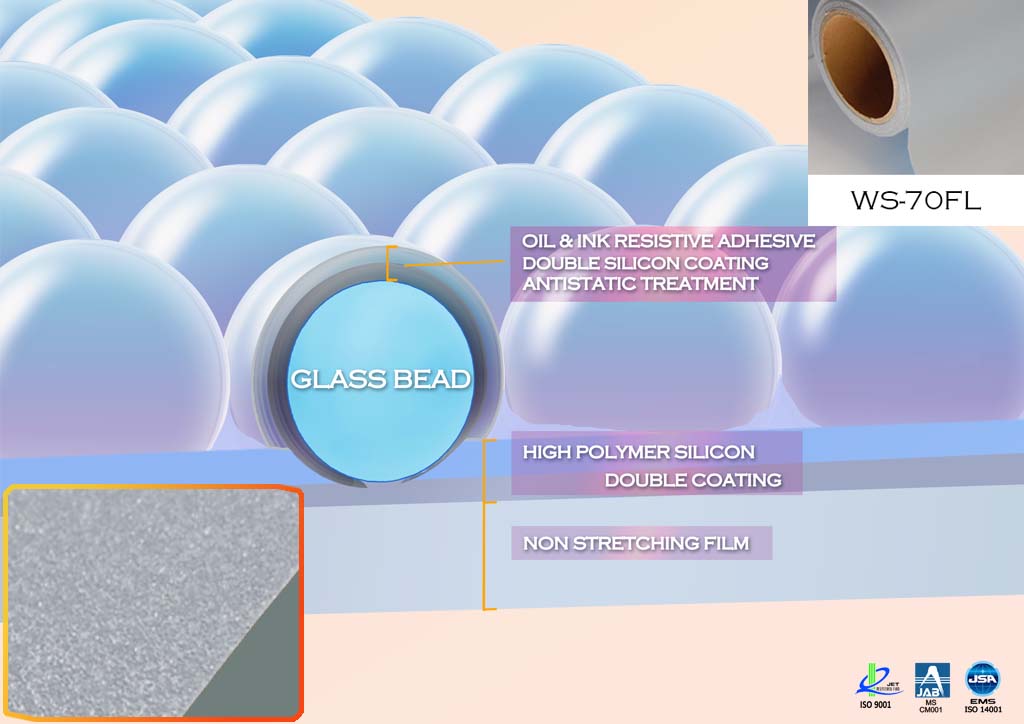

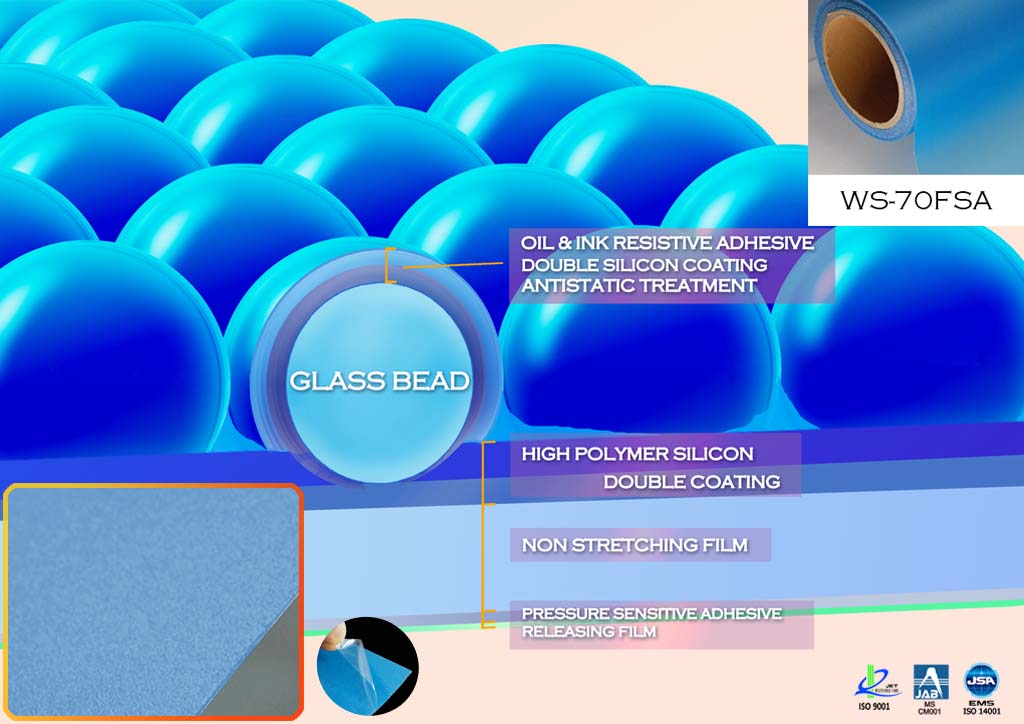

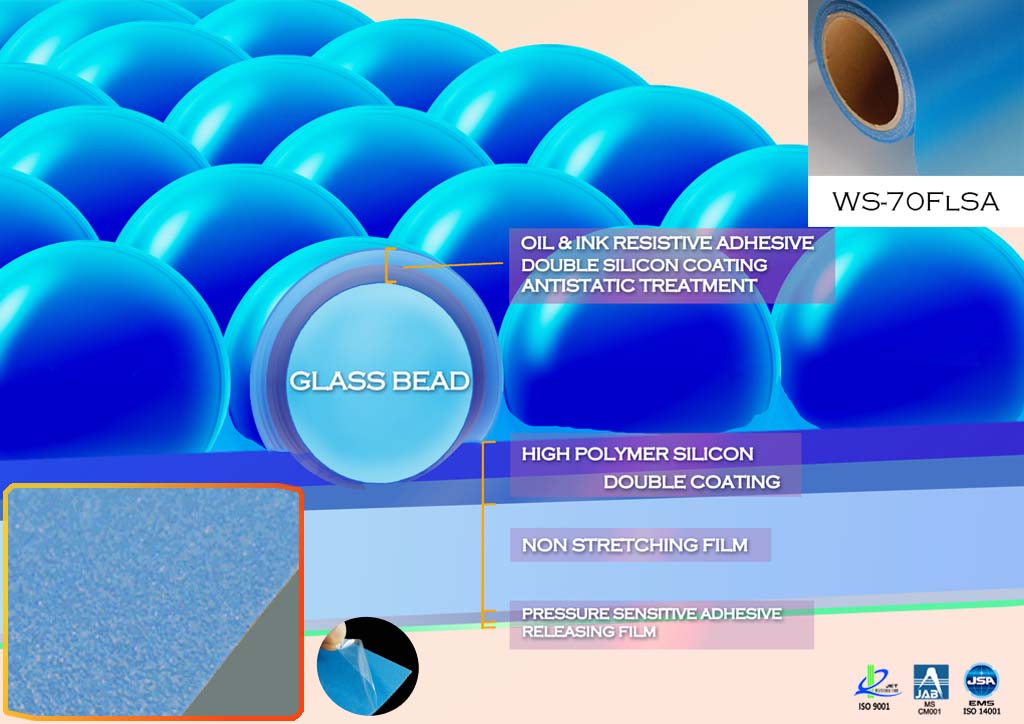

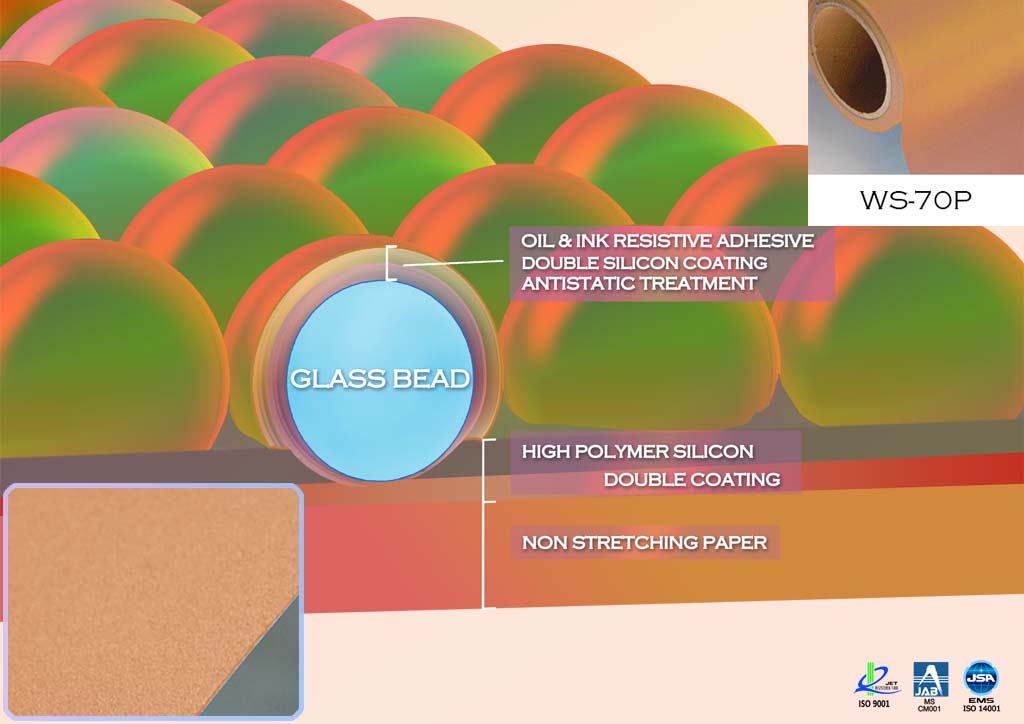

OHDEN Original Anti-Marking Film

- Japanese coating technology certified by ISO9001 quality control

- Double coating treatment firmly ensure ink and oil resistance.

- It firmly repels ink and releases clean printed paper without markings.

- Antistatic coating prevents static buildup on printed paper.

- Available with or without adhesive on the backing.

Advantages Of The Original Anti-Marking Film Utilizing Superior Japanese Coating Technology

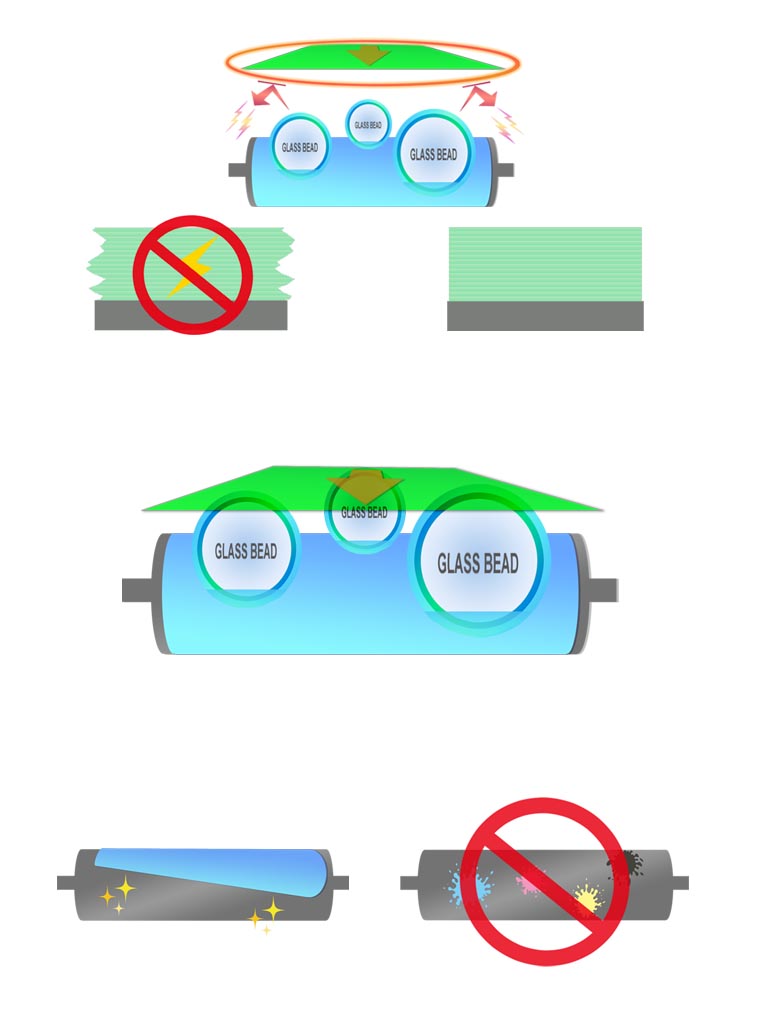

Antistatic

Special silicone-coated glass particles with antistatic effect prevent static electricity generation on the paper and reduce the paper misalignment factor at delivery.

Run the press at higher speed without marking & paperjam

Special silicone-coated glass particles with oil-resistant performance reduce the contact area of the inked paper, allowing the paper to be fed smoothly and preventing rubbing/scratches and other defects from occurring on the printed surface.

Minimize down time due to cleaning the press cylinders

Prevents ink from accumulating on the transfer cylinder and saves time and effort in cleaning the transfer cylinder.

What Benefits Do Printing Press Material Distributors Gain From Handling Anti-Marking Film?

Increased Sales

By offering anti-marking film as a product, distributors of printing press materials can expand their product line and potentially increase sales.

Anti-marking film is an essential product for many printing presses, and distributors who offer it can attract more customers.

Improved Customer Satisfaction

By offering anti-marking film, distributors of printing press materials can help their customers improve print quality and reduce waste.

This can lead to higher customer satisfaction, as customers are more likely to return to distributors who can help them achieve their desired results.

Competitive Advantage

Not all distributors of printing press materials offer anti-marking film, so those who do can gain a competitive advantage in the marketplace.

This can help them attract new customers and retain existing ones.

What Benefits Do Operators Get From Using Anti-Marking Film?

Improved Print Quality

Anti-marking film helps to prevent ink transfer and smudging during the printing process, resulting in cleaner and more consistent print quality.

Reduced Downtime

Marking on printed sheets can cause printing presses to stop or require additional cleaning, which can result in downtime for the operator.

Anti-marking film can help reduce the frequency of these issues, reducing downtime and increasing productivity.

Increased Efficiency

With fewer interruptions from marking and cleaning, operators can work more efficiently and produce more printed sheets in a shorter amount of time.

Lower Waste

Marked or smudged sheets may need to be discarded or reprinted, which can result in wasted paper and ink.

Anti-marking film helps reduce the likelihood of these issues, leading to lower waste and more efficient use of resources.

Reduced Maintenance Costs

Marking and smudging can lead to increased wear and tear on printing presses, requiring more frequent maintenance and repair.

Anti-marking film can help reduce the need for these costly interventions, leading to lower maintenance costs and increased longevity for the printing press.

Adaptable sheet-fed printing presses

Anti-marking film - product style

How to install

1

2

3

4

5

6

- Define the film size.

- Cut the film.

- Clean the cylinder.

- For adhesive type, cut a slit in both ends of the release film; for non-adhesive type, apply double-sided tape to both ends.

Peel off the release film on one side or peel off the double-sided tape on one side. - Affix it to the cylinder.

- Rotate the cylinder while pressing the inching button on the press.

Peel off the release film on the opposite side of the film, or peel off the double-sided tape on the opposite side and affix it to the cylinder.

Our Proposal to You

Better Quality

Why don’t you review its quality?

Lower Cost

Are you satisfied with those prices?

Greater Reliability

Why not gain more reliability from your customers?

OHDEN Limited - Operations Office

1-4-16, Sakaebashicho, Sakai-ku, Sakai City, Osaka 590-0971 JAPAN

Phone

+81 72 245 9322

sales@ohden.com

Any other requirements for Japanese printing materials of high quality and suitable price?

We may be able to offer you the best solution by utilizing our many years of experience and extensive network.

Business Categories